Welcome to the official website of Nantong Sofya Stone Co., Ltd.!

These four categories, so that you have a comprehensive understanding of the stone "surface article" Chinese stone network

2021-08-15

In addition to the natural texture of stone to bring people unique natural artistic visual effects, but also through a variety of surface processing methods, to create a variety of visual experience. Such a rich change is also one of the charm of stone.

By doing "superficial articles", stone can not only fully display its own charm, but also have the opportunity to improve its own visual defects and enhance its value in the eyes of consumers.

Stone surface treatment

Stone surface treatment refers to the use of different processing treatments on the surface of the stone to ensure its own safety, so that it presents different material styles to meet various design requirements.

Take marble as an example, its surface treatment is very important, because designers will choose the appropriate surface treatment form according to the type and pattern of stone, the degree of hardness and characteristics, and then present it in the indoor space, so as to better ensure the effect of design works, meet the design requirements of safety, functionality and aesthetics, and avoid some design problems.

There are many forms of surface treatment of marble. From the perspective of anti-skid, stain resistance, easy cleaning and anti-collision, different surface treatment methods can be extended.

So, what are the more common stone surface processing methods in the industry?

According to the actual use, it can be roughly divided into the following four categories:

One is the most conventional surface treatment, such as polished surface, matte surface, etc;

The second is non-slip surface treatment, such as pickling surface, fire surface, cloth pattern surface, water spray surface, litchi surface, pineapple surface, etc;

The third is decorative surface treatment, such as antique surface, trough surface, mushroom surface, natural surface, sandblasting surface, pickling antique surface, etc;

Fourth, the engraving plate and special surface treatment, as long as you can think of the surface texture can be achieved, such as crocodile skin carving, water pattern carving and so on.

Below we will give you one by one to introduce

Different surface treatment methods of stone

-PART01-

Conventional surface treatment

1. Polished surface

Polishing surface refers to the surface made by rough grinding, fine grinding and fine grinding of the plate with abrasive, and polishing powder and agent. The surface is mirror-like, brightly colored, with few and very small pores.

General stone luminosity can be 80, 90 degrees, which is characterized by high luminosity, strong reflection of light, often can fully display the rich and gorgeous color and natural texture of the stone itself.

After matte treatment of stone, often has a certain luminosity, but the reflection of light is weak, is a smooth surface, but the low luminosity of the plate.

-PART02-

Anti-slip surface treatment

1. Pickling surface

Pickling surface is through the use of strong acid corrosion stone surface to achieve the visual effect, after treatment of stone, the surface will have less corrosion traces, than polished surface looks more pristine, and strong acid does not affect the stone inside.

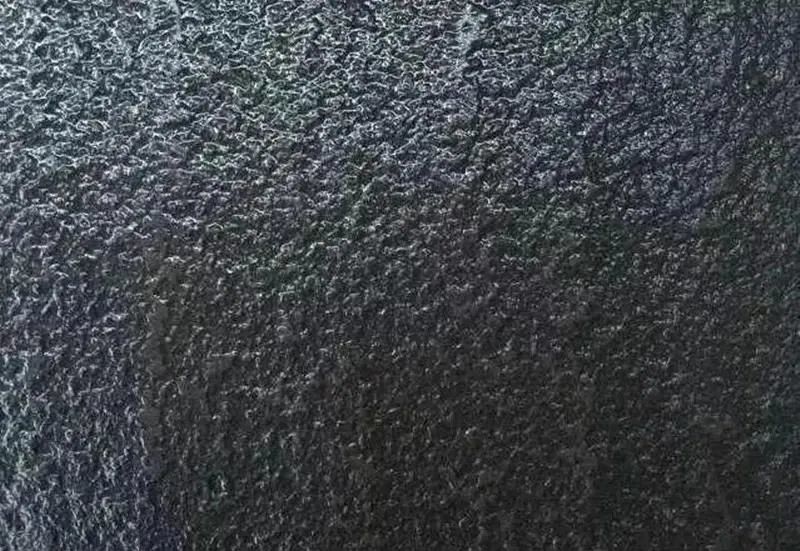

2. Fired noodles

Fire surface refers to the use of acetylene, oxygen as fuel or propane, oxygen as fuel, or with liquefied petroleum gas and oxygen as fuel to produce high-temperature flame on the stone surface processing of rough finish.

Due to the effect of fire can burn off some of the impurities and low melting point of the stone surface, thus forming a rough finish on the surface, so the hand will feel a certain sense of thorn.

The processing of the burnt surface has certain requirements on the thickness of the marble. Generally, the thickness of the stone is at least 20mm and the surface is crystallized to prevent the stone from cracking during the processing.

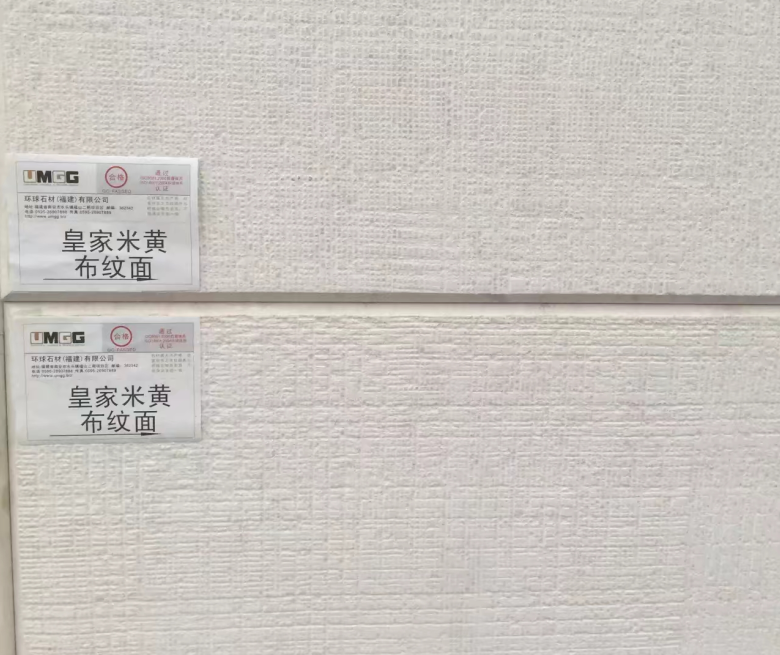

3. Cloth surface

The practice of cloth surface is to treat the stone surface into cloth texture, which can retain the texture of stone and imitate the texture of wallpaper, giving people a feeling of wall cloth.

4. Washing surface

The stone surface is rinsed by water knife machining, showing uneven shape, but the surface is smooth without edges and corners, which is similar to the pickling surface, but the surface color is close to the smooth surface, slightly deeper than the pickling surface, and the water absorption rate is small.

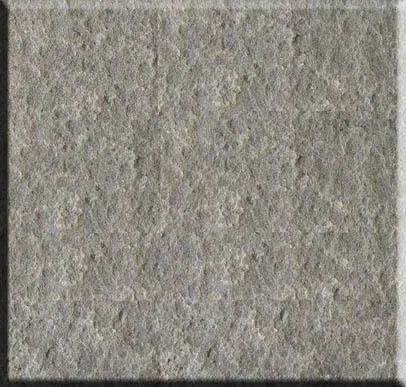

5. Litchi Surface

The litchi surface is formed by knocking on the granite surface with a hammer shaped like litchi skin. After treatment, the stone surface will form a rough surface shaped like litchi skin, which is uneven. This treatment method can be divided into two types: machine face (machine) and hand face (manual). Generally speaking, hand face is finer than machine face, but it is more laborious and the price is relatively higher.

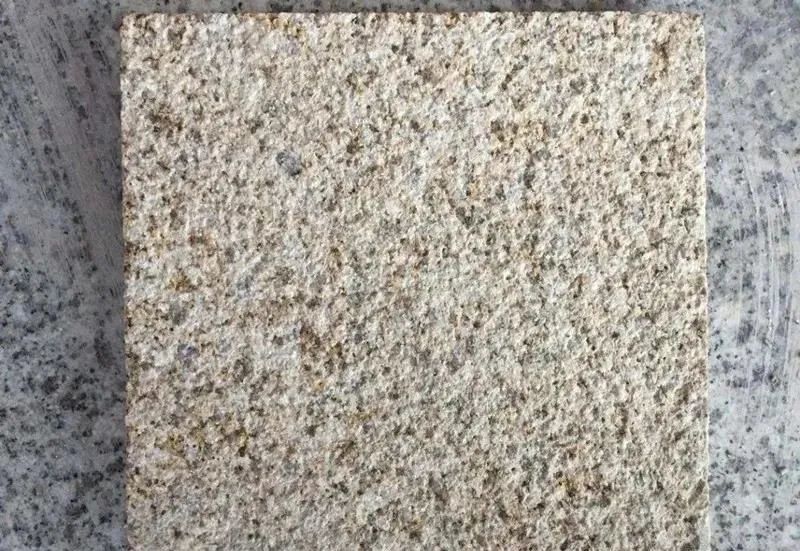

6, pineapple noodles

The practice of pineapple surface is to make the stone surface more uneven than litchi surface, and the graininess is more obvious. Its material texture is just the opposite of the washed surface, with weak concave and convex feeling and large graininess.

-PART03-

decorative surface treatment

1. Antique surface

Antique surface is to eliminate the characteristics of burning surface prickly hand, in the stone first with fire, and then use steel brush brush 3-6 times, that is, antique surface. The antique surface has the concave and convex feeling of the fire surface, and it feels smooth and does not sting the hand. It is a very good surface treatment method. The processing of antique surface is time-consuming and expensive.

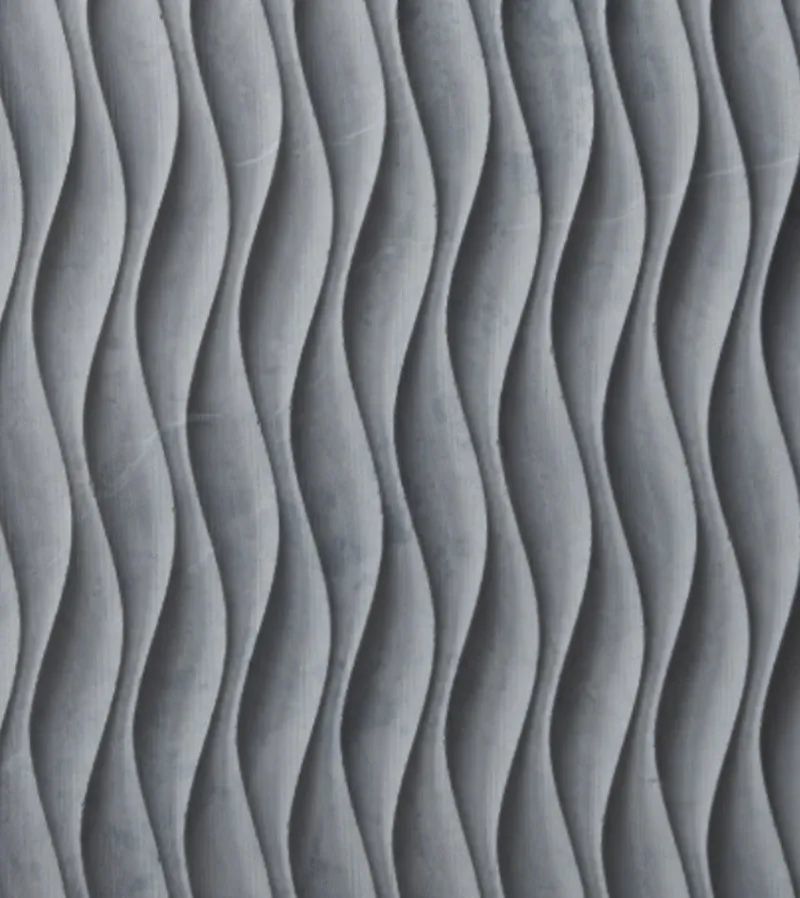

2. Groove surface

The groove surface is also called "groove" or "wire drawing", which is a groove with a certain depth and width on the stone surface. It is usually a straight groove, with two-way groove (5mm × 5mm) and one-way groove. If required, a water knife can also be used to pull the curved slot, but the material cost is relatively high.

In order to avoid accidental injury, the use of this approach to consider the notch passivation treatment, if necessary, can do grinding.

Recently popular format elements can be used to process stone in this way.

3. Mushroom noodles

Mushroom surface refers to the stone surface with a chisel and hammer percussion shape like undulating mountain plate. This processing method has certain requirements for the thickness of the stone. Generally, the bottom should be at least 3cm thick, and the raised part can be more than two cm according to the actual requirements. This processing method is common in the economic fence.

4. Natural face

The natural surface is commonly known as the natural fracture surface and the cracking surface. It uses machinery to split a piece of stone from the middle naturally. After splitting, it does not undergo any treatment. The surface of this stone is extremely rough and extremely uneven. Under the irradiation of light, it appears to be particularly tense.

Natural marble should also consider the relationship between stone weight, thickness, specifications and installation process, suitable for natural style, rough style space.

5. Sand blasting surface

Natural stone sandblasting (stone sandblasting surface) is the use of edged carborundum, quartz sand, river sand and other abrasives in compressed air (or water) driven by the impact on the stone surface, the resulting a similar glass grinding effect of stone surface processing.

Now the process is generally realized by the stone sandblasting machine, which can adjust the air flow size according to the hardness of the stone to achieve the required depth and uniformity.

This processing method can make the stone have a good anti-skid function without losing its beauty, so the application range is very wide. It can not only be used for the processing of natural stone plate products such as thin plates and specification plates, but also can process special-shaped stones such as lines, pillars, railings, steps and corners, and sandblasting is also widely used in stone carving, in hotels, conference rooms, museums, corridors and other occasions can often be seen.

6. Pickling antique surface

-PART04-

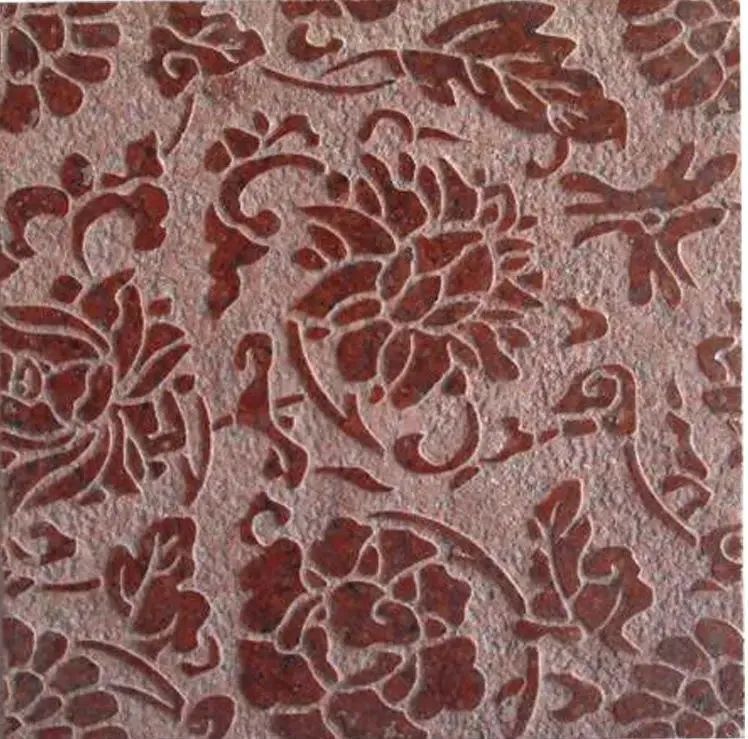

Engraving board and special surface treatment

As long as you can think of the surface texture, can be achieved through the form of engraving, marble engraving plate and special surface treatment of the decorative effect is very beautiful, excellent.

I believe that in the future development, as consumers understand and use the stone industry, the types of stone products will only become more diverse.

Related news